![]()

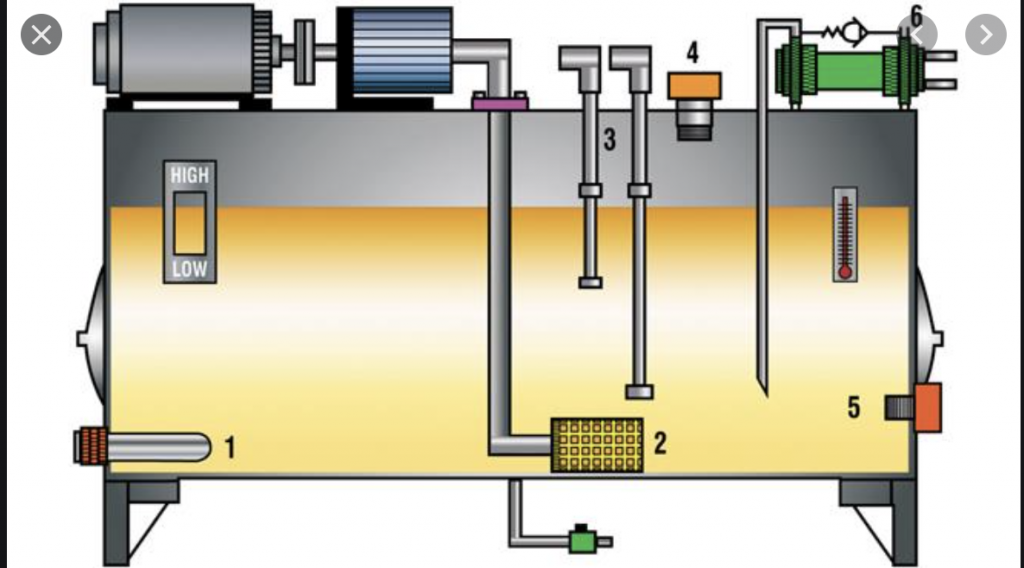

The machines in modern life are as complex as the lives in this era. It is essential to go for proper upkeep and maintenance of the devices to extend their lives. These machines require periodic checking and inspection and can reduce productivity and fewer benefits if not done in a manner. The machines are subject to daily wear and tear, and if we become negligent, we will have to pay huge losses. One fault in the device can put us in massive trouble, so it is recommended not to go for cost-cutting measures. One such example of a very complex machine is a hydraulic system that is used for energy transmission, which enables work to be accomplished. They are also responsible for heat transmission, lubrication, and contamination control. The hydraulic system puts the fluid under pressure to move the giant machinery and other mechanical components. The benefits they provide to us are uncountable. Proper hydraulic system maintenance is essential to ensure that the machine performs in works and gives us desired results. There is a list of preventative measures and the programs which can be undertaken to prevent the breakdown of the machinery. So let’s be familiar with the tips to expand the life of the hydraulic system:

checking of fluids: Since the hydraulic system uses the hydraulic fluid to operate the machinery, this must be the foremost priority for everyone to keep a check on fluids. The liquids must not be mixed as all are of different brands and viscosity. Do not go for overfilling and only out the required quantity of fluids. Consider fluid maintaining practices and ensure your system is not overheated and is not operated in a filthy environment.

Check your filter indicators: The indicator’s role is to tell out the amount of contamination caught in the system. This can be indicated visually or electrically. Once the filter reaches its maximum limit of contamination, it has to be replaced.

Check all the pipe and pipe connections: Fluid leakage is the biggest shortcoming of the hydraulic system. Visual inspection of the lines, hoses, and pipe connections is vital to prevent fluid from leaking and bubbling. Excessive leakage should be stopped at any cost as it is an environmental hazard and will lead to a lot of oil consumption. The regular functioning of the machine is disrupted, thereby leading to more problems.

Measure the temperatures: Temperature check is crucial to regulating the oil’s viscosity. Temperatures are checked using inbuilt thermometers and infrared detectors. Low density reduces the thickness between the moving components, and high density can cause excessive pressure.

Keep your equipment clean: It is vital to keep your kits clean as the dirt can reduce their functioning. The grime can enter inside the equipments when disconnected from the system.

Performance evaluation: Any hydraulic is expected to slow its performance over time. It is necessary to monitor the actuator speed, checking temperatures, and keep the proper fluid requirements so that the hydraulic system can perform its functions smoothly and effectively.