![]()

A hydraulic system would power all the significant equipment in your production. It can be used for every task, even a simple one like lifting up some stuff. If there were problems with the hydraulics, the machine would stop functioning. Therefore, it is essential to have the right tools in order to fulfil deadlines and prevent delays. It would help you avoid production issues and guarantee that the hydraulics operate properly. Work with a hydraulics dealer immediately to acquire the finest offers and models. If you do not know, then you would benefit from their expertise; ask them what would work best.

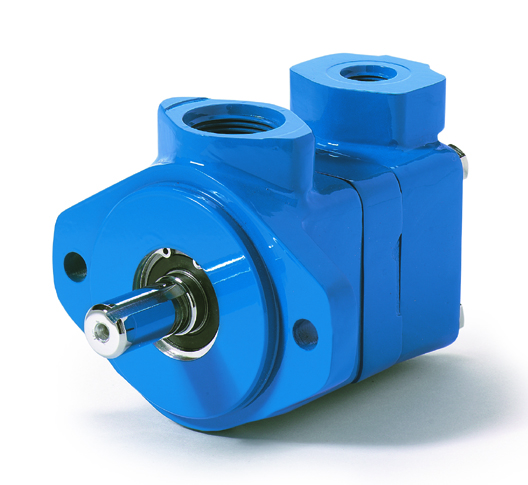

Hydraulic pumps

One of the most widely used systems in hydraulics is hydraulic pumps. Due to repair costs or mission-criticality, several hydraulic system components, such as pumps and valves, are considered essential. In hydraulic drives, hydraulic pumps transform mechanical forces into hydraulic energy. As a result of the vacuum that is formed inside the pump, the fluid is under pressure to exit the reservoir. Different kinds of dynamic machinery run on hydraulic pumps. They can spin several components and can push massive volumes of liquid. If the hydraulic pumps’ fluid leaks, the sector might have catastrophic effects. When the system’s particles move, they collide with one another and scuff up against the walls of the container. The liquid is moved from one location to another by applying pressure uniformly in all directions.

Advantages of hydraulic pumps

- The hydraulic system’s minimal moving parts are among its most notable benefits. The constant wear and tear of moving parts necessitate frequent repairs.

- The hydraulic pumps can ice up with no issues.

- They are employed in nearly all commercial and industrial applications.

- The energy economy of hydraulic pumps is another reason they are employed in various tasks. As a result, using hydraulic pumps is simple because they don’t entail any complicated mechanisms.

- In all industries, hydraulic pumps are extensively used; they are used in practically all facets of life.

- They are the most important source of energy and mechanical power.

- They are designed to force heavy volumes of fluid within the metal cylinders.

- The hydraulic pumps are utilized in this mechanism to convert energy from one form to another.

- It involves resolving water issues and supplying safe drinking water in less developed places.

Types of hydraulic pumps

Vane pumps: Vane pumps come in a wide variety, depending on the manufacturer. Vane pumps are expensive, but they provide a constant flow. They operate using comparable design tenets. A cam ring that is offset or eccentric to the drive shaft rotates inside a slotted rotor linked to the drive shaft. Vanes are put into the rotor slots and spin with the rotor while following the cam ring’s inner surface. Because they are constantly in contact, the vanes and the inside surface of the cam rings experience significant wear. The vanes move away from their slot as the two surfaces deteriorate. Vane pumps might not be appropriate in critical high-pressure hydraulic systems where contamination and fluid quality are challenging.

Piston pump: Fixed and variable displacement versions of piston pumps are available. The piston pump is the most adaptable and durable form of pump, which provides various alternatives for any system. They make relatively little noise and are very effective.